Offering a prognosis in unconventional “shale” requires a description of the host formation, the “artificial” reservoir, which is created by human intervention, and an understanding of the related physics. Formation properties and the earth stresses are conducive to establishing the artificial reservoir, which is induced by hydraulic stimulation. In a classic view of hydraulic fracturing, injected fluids permeate into he formation raising the pore pressure to the point that it counters the least of the principle stresses and gives form to a planar hydraulic fracture. In unconventional development this does not apply exactly.

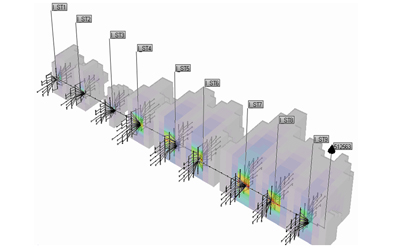

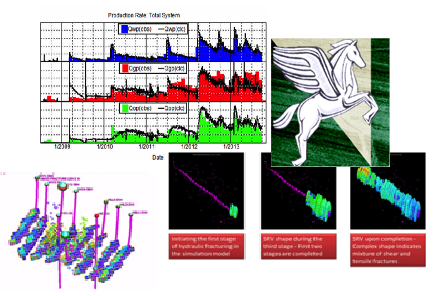

The formations are not conducive to fluid permeation to their pores, instead the stresses imposed to the walls of a horizontal well can cause shear failure in the rock vicinity. Shear failure and the mechanical heterogeneities that exist (fractures, bedding planes, faults, etc..) create a complex network of fracturing exposing large surface areas. Injected fluids penetrate the formation that way and cause a gradual degradation of the formation to the point that it develops throughways of hydraulic fracturing. The mechanics of shearing and hydraulic fracturing are complicated and require the coupling of geomechanics to fluid mechanics in fractures and porous media. A simplified approach we proposed in 2010 led to the adaptation of dilation curves into reservoir simulation models, which are capable of describing the gradual generation of the artificial reservoir during hydraulic stimulation and the flow behavior afterwards.

This approach was validated when used in a pilot project, which offered rich petrophysical, microseismic, and production surveillance. In that project the role of proppant was isolated as it was found by the operators that it was necessary and the study really shed light to the nature of complex fracturing mechanics. It was successful in constraining the uncertainties in production predictions providing a reliable projection, which was later found to coincide with the type curve average of more than 3,000 similar wells. As the shale engineering became a tool in offering predictions in places that it was not possible otherwise (like in China, Europe, etc..) it also became a workbench of optimizing development and completion practices.

The latter was and is the focus of Nitec LLC as their founder, Chet Ozgen, came to a parallel conclusion independently. During my tenure at Repsol, I had a chance to employ Nitec’s services and that process has led us to a great turnaround of a very challenging play. Presently after leaving Repsol, I founded Nitec Pegasus LLC in partnership with Mr. Ozgen in order to promote the use of shale engineering beyond the asset level, which is the typical Nitec clientele, to the planning and strategic level, which would eventually conform to the principles of modular development.

George D. Vassilellis, Charles Li, Vivian K. Bust/ Gaffney, Cline and Associates; Daniel Moos and Randal Cade, “Shale Engineering Application: The MAL-145 Project in West Virginia”, SPE 146912, presented, Canadian Unconventional Resources Conference held in Calgary, Alberta, Canada, 15–17 November 2011.

Daniel Moos, G. Vassilellis, R. Cade, J. Franquet, Baker Hughes; A. Lacazette, Bourtembourg, G. Daniel, “Predicting Shale Reservoir Response to Stimulation in the Upper Devonian of West Virginia”, SPE 145849, Annual Technical Conference and Exhibition held in Denver, Colorado, USA, 30 October–2 November 2011.

George Vassilellis, Chao Li, Rawdon Seager, Daniel Moos, “Investigating the Expected Long-Term Production Performance of Shale Reservoirs”, CSUG/SPE 138134, Calgary, Alberta, Canada, October 20th, 2010.