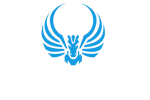

Heavy oil accumulations are a respectable 3.5 trillion barrels of untapped petroleum potential worldwide. In comparison the world has produced 1 trillion barrels, while the remaining reserves amount to about as much. Currently, less than 5% of the world’s production is sourced from heavy oil, the majority coming from surface mined tar sands. Existing thermal technologies apply successfully in relatively shallow accumulations at less than 3000 feet. Having worked in many heavy oil fields worldwide, I have developed a reliable analytical tool which can be used to provide oil production forecasts based on injected steam volumes using analytical thermodynamic models which are tuned to field dynamics

This can be applied in continuous or cyclic steam injection and even in horizontal well SAGD configurations as shown in the example above. This thermal balance method can be used also to upscale detailed thermal modeling using thermal simulation such as CMG STARS. Thermal reservoir modeling addresses fluid dynamics more precisely and it is necessary to use in order to design spacing, placement, completion design and even hydraulic fracturing.

In order to develop deeper heavy oil accumulations that need heat in order to mobilize heavy oil, downhole steam generation (DHSG) can be used to compensate for heat losses and a higher pressure regime. In the last 10 years I have worked closely with a technology start up group, World Energy Systems (WES) which have designed such a tool

This can be applied in continuous or cyclic steam injection and even in horizontal well SAGD configurations as shown in the example above. This thermal balance method can be used also to upscale detailed thermal modeling using thermal simulation such as CMG STARS. Thermal reservoir modeling addresses fluid dynamics more precisely and it is necessary to use in order to design spacing, placement, completion design and even hydraulic fracturing.

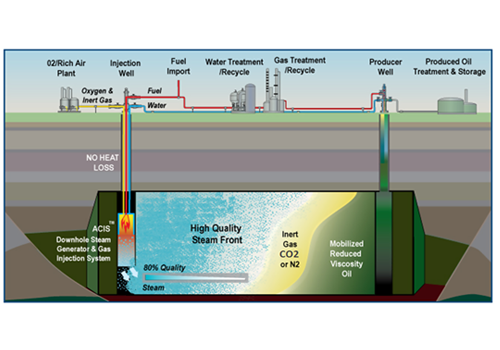

In order to develop deeper heavy oil accumulations that need heat in order to mobilize heavy oil, downhole steam generation (DHSG) can be used to compensate for heat losses and a higher pressure regime. In the last 10 years I have worked closely with a technology start up group, World Energy Systems (WES) which have designed such a tool and have conducted a series of feasibility studies in Alaska , California, Middle East and other places.

The premise behind this design is to inject into a downhole burner the fuel, oxygen rich mixtures and water, generating high quality steam. The patented low temperature tip and the ability to carry dissolved solids through a hot liquid phase distinguish this tool from previous unsuccessful attempts in downhole steam generation. There are other advantages in this implementation, as thermal processes combined with injected CO2 and excess O2, result to very high recovery factors which may approach 80% in a SAGD confuguration. The high pressure window enables not only the development of deeper formations, but provides a displacement drive in tighter formations.

George Vassilellis, Repsol, Laura Capper, Cap Resources, Myron Kulhman, Mk Solutions: “Downhole Burners: Pushing the Envelope of Enhanced Oil Recovery in the Artic” International Society of Offshore and Polar Engineering (ISOPE), International Symposium, Anchorage Alaska, June 30-July 5, 2013

George D. Vassilellis, Myron I. Kuhlman, Marvin Snyder, “Advancing Thermal and Carbon Dioxide Recovery Methods Beyond their Conventional Limits: Downhole Innovation”,SPE-150515, to be presented at SPE Heavy Oil Conference and Exhibition, Kuwait City, Kuwait,12 – 14 Dec 2011. Highlights of this article were published in the JPT magazine “Downhole Steam Generation Pushes Recovery Beyond Conventional Limits” edited by Adam Wilson, June 2012 edition. Discussion follows in the September 2012 JPT edition.