As a consultant in California in late 1990’s and early 2000’s, I have witnessed the transformation of our industry in its inception. During a significant Permian Basin project in 2003 focused on tight gas, I proposed, designed and demonstrated the economic benefits of drilling horizontal wells with transverse hydraulic fractures. At that time such novelty could not be supported by hydraulic fracture staging tools and the idea of perf and plug emerged. Our client Dominion followed up with several wells in the Strawn, while as some of the key engineers later moved to Devon, this became a common practice in Barnett shale c. 2005.

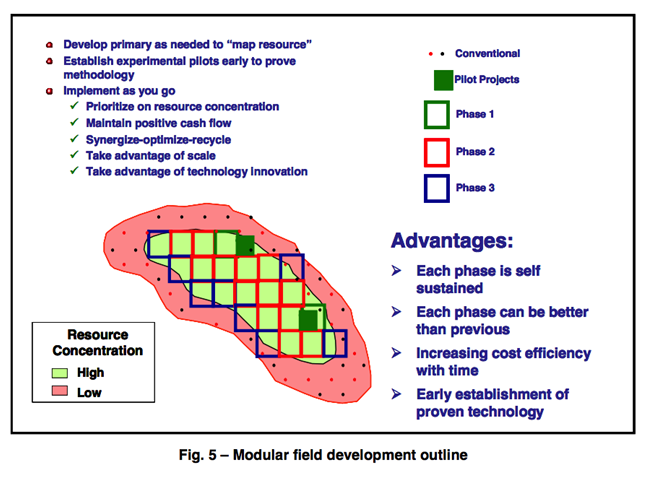

The modular approach brought a paradigm change at Baker Hughes who bought our consultancy in 2008. I was immediately brought to the forefront of their unconventional operations and became a Subject Matter Expert in that field. The immediate impact was concentrated piloting programs in frontier projects especially for the ones outside the US which shortened the proofing cycle significantly accelerating the learning curve. Baker Hughes (as they acquired BJ Services) also changed the frac fleet to dual fuel and introduced surface ESP’s in order to materialize the cost savings brought by the modular approach.

This approach also emphasized the need to develop prognostic tools based on geological description, which led to further research in an effort to improve this ability. I coined the term “shale engineering” as opposed to reservoir engineering to recognize the departure from conventional oilfield practices and understanding.